SPOILER ALERT!

Enhancing Efficiency: Streamlining Your Manufacturing Procedures With Tunnel Pasteurization Technology

Web Content Author-Didriksen Childers

Tunnel pasteurizers are big industrial-scale devices that warmth and trendy beverages in order to kill microbes and prolong their shelf life. Their performance depends on accuracy control.

Numerous beverage business have retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly innovations to attain substantial ecological advantages. These consist of minimized power usage, lower water usage and lowered greenhouse gas exhausts.

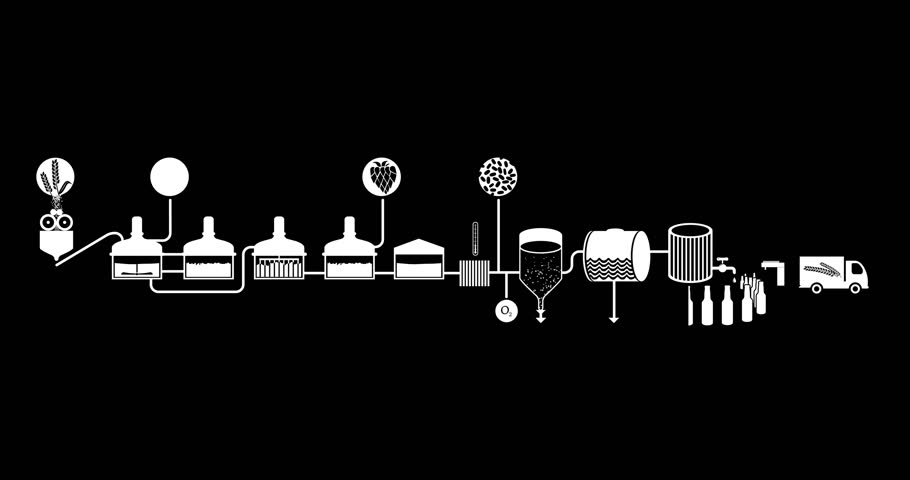

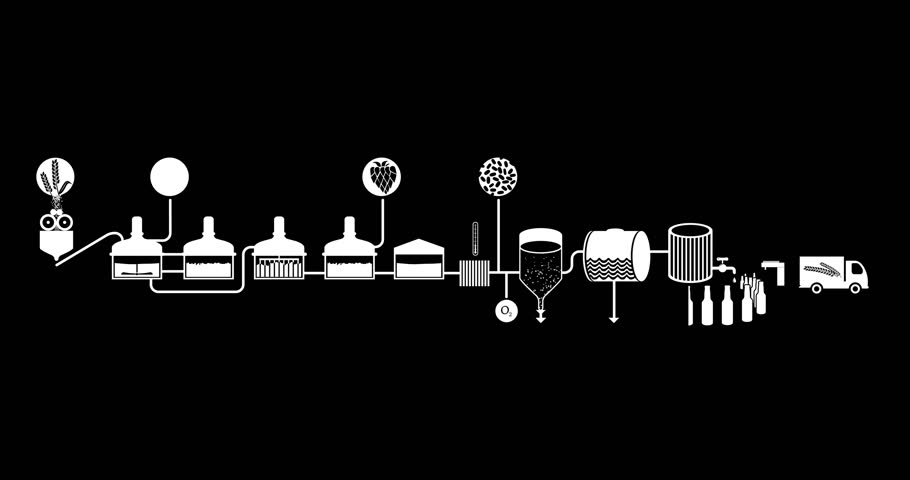

When you run a brewery, your goal isn't simply to get rid of harmful microorganisms, but likewise to supply uniformity in your products. A well-executed pasteurization process not only lengthens beer's shelf life, but it guarantees that every container of your beer will taste the exact same, from your first set to your last. This is especially essential for craft breweries aiming to bring in health-conscious clients who want the fizzy goodness of soft drinks.

Tunnel pasteurizers function by bringing bottles and cans approximately their preferred temperature level in stages, holding them there for enough time to exterminate the bacteria that trigger spoilage. They then bring them down once again in step-by-step steps till they get to space temperature, protecting preference accounts. By doing this, they not only avoid microorganisms from increasing in the product, however they likewise lower power intake by removing warmth loss. These are the sort of performance gains that can add up rapidly.

As more focus is placed on eco-friendly production methods, drink producers are searching for ways to minimize their waste manufacturing. Tunnel pasteurizers do a terrific work of this, particularly when they are designed and built by seasoned experts.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or canisters as they relocate through the device. This eliminates the requirement for a big heavy steam container that eats energy and drainages. In addition, Tunnel pasteurizers utilize a water financial savings system to reuse the hot water utilized in the heating process, which minimizes water and sewer usage.

One more advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing point for craft brewers who want to extend their products' life span and make certain uniformity between batches. Unlike https://www.foodsafetynews.com/2019/04/new-zealand-officials-seek-feedback-on-rules-for-unpasteurized-raw-milk/ , which occasionally have problem with high degrees of carbonation, Tunnel devices can manage these bubbly mixtures without breaking a sweat (or a container).

When your beverages are effectively treated in Tunnel pasteurizers, they're safeguarded from dangerous germs while maintaining their taste accounts. This suggests your mixtures, soft drinks, acid maintains (like fruits or acids), and health shots can expand their life span without losing their signature taste.

In order to accomplish this, passages feature exact temperature control and even circulation throughout their multiple stages. In addition, conveyor belt speeds aid guarantee equal therapy times for each container getting in the equipment. All this helps you assure quality outcomes each time.

Finally, passages work with carbonated beverages, an expanding pattern among health-conscious consumers searching for carbonated choices to sweet sodas. Unlike flash pasteurizers, which can battle with high-carbonation degrees, Tunnel makers are made to manage them.

Additionally, retrofitting passages with energy healing systems decreases water use too. By using the retrieved water for cooling, you'll significantly cut your power intake and greenhouse gas discharges.

Tunnel pasteurizers are energy-intensive makers, however you can minimize your power usage by retrofitting them with cutting-edge eco-friendly innovation. This consists of solar-powered burner that can work on renewable energy resources, decreasing reliance on fossil fuels and your carbon footprint.

One more excellent feature of Tunnel pasteurizers is that they work with carbonated beverages, a popular fad amongst today's health-conscious customers. Unlike flash pasteurizers, which in some cases fight with high-carbonation degrees, Tunnel systems can manage these fizzy concoctions easily.

zPasteurAIzer can monitor the efficiency of your existing Tunnel pasteurizer by estimating the accumulated product high quality (PU) worth for each set. https://www.growingproduce.com/nuts/project-aims-to-create-guidelines-for-pistachio-pasteurization-validation/ enables you to establish if your existing temperature level control system is supplying enough warmth therapy along with identifying any type of curved spray heads. You can then change the machine settings based upon your preferred PU worths, boosting manufacturing effectiveness while decreasing energy intake. This is a wonderful means to cut down your water consumption too, aligning your organization with consumer demand for eco responsible products.

Tunnel pasteurizers are big industrial-scale devices that warmth and trendy beverages in order to kill microbes and prolong their shelf life. Their performance depends on accuracy control.

Numerous beverage business have retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly innovations to attain substantial ecological advantages. These consist of minimized power usage, lower water usage and lowered greenhouse gas exhausts.

1. Enhanced Performance

When you run a brewery, your goal isn't simply to get rid of harmful microorganisms, but likewise to supply uniformity in your products. A well-executed pasteurization process not only lengthens beer's shelf life, but it guarantees that every container of your beer will taste the exact same, from your first set to your last. This is especially essential for craft breweries aiming to bring in health-conscious clients who want the fizzy goodness of soft drinks.

Tunnel pasteurizers function by bringing bottles and cans approximately their preferred temperature level in stages, holding them there for enough time to exterminate the bacteria that trigger spoilage. They then bring them down once again in step-by-step steps till they get to space temperature, protecting preference accounts. By doing this, they not only avoid microorganisms from increasing in the product, however they likewise lower power intake by removing warmth loss. These are the sort of performance gains that can add up rapidly.

2. Reduced Waste

As more focus is placed on eco-friendly production methods, drink producers are searching for ways to minimize their waste manufacturing. Tunnel pasteurizers do a terrific work of this, particularly when they are designed and built by seasoned experts.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or canisters as they relocate through the device. This eliminates the requirement for a big heavy steam container that eats energy and drainages. In addition, Tunnel pasteurizers utilize a water financial savings system to reuse the hot water utilized in the heating process, which minimizes water and sewer usage.

One more advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing point for craft brewers who want to extend their products' life span and make certain uniformity between batches. Unlike https://www.foodsafetynews.com/2019/04/new-zealand-officials-seek-feedback-on-rules-for-unpasteurized-raw-milk/ , which occasionally have problem with high degrees of carbonation, Tunnel devices can manage these bubbly mixtures without breaking a sweat (or a container).

3. Much Better Item High Quality

When your beverages are effectively treated in Tunnel pasteurizers, they're safeguarded from dangerous germs while maintaining their taste accounts. This suggests your mixtures, soft drinks, acid maintains (like fruits or acids), and health shots can expand their life span without losing their signature taste.

In order to accomplish this, passages feature exact temperature control and even circulation throughout their multiple stages. In addition, conveyor belt speeds aid guarantee equal therapy times for each container getting in the equipment. All this helps you assure quality outcomes each time.

Finally, passages work with carbonated beverages, an expanding pattern among health-conscious consumers searching for carbonated choices to sweet sodas. Unlike flash pasteurizers, which can battle with high-carbonation degrees, Tunnel makers are made to manage them.

Additionally, retrofitting passages with energy healing systems decreases water use too. By using the retrieved water for cooling, you'll significantly cut your power intake and greenhouse gas discharges.

4. Minimized Power Consumption

Tunnel pasteurizers are energy-intensive makers, however you can minimize your power usage by retrofitting them with cutting-edge eco-friendly innovation. This consists of solar-powered burner that can work on renewable energy resources, decreasing reliance on fossil fuels and your carbon footprint.

One more excellent feature of Tunnel pasteurizers is that they work with carbonated beverages, a popular fad amongst today's health-conscious customers. Unlike flash pasteurizers, which in some cases fight with high-carbonation degrees, Tunnel systems can manage these fizzy concoctions easily.

zPasteurAIzer can monitor the efficiency of your existing Tunnel pasteurizer by estimating the accumulated product high quality (PU) worth for each set. https://www.growingproduce.com/nuts/project-aims-to-create-guidelines-for-pistachio-pasteurization-validation/ enables you to establish if your existing temperature level control system is supplying enough warmth therapy along with identifying any type of curved spray heads. You can then change the machine settings based upon your preferred PU worths, boosting manufacturing effectiveness while decreasing energy intake. This is a wonderful means to cut down your water consumption too, aligning your organization with consumer demand for eco responsible products.